-

Lapping Machine

Lapping Machine- Double side polisher

- Single side polisher

- Single side grinder -

Cleansing Machine

Cleansing Machine- 9 tanks in-line ultrasonic

- 8 tanks in-line ultrasonic

- 3 tanks in-line ultrasonic -

Coating Machine

Coating Machine- E-beam evaporator

- E-beam evaporator + Ion source

- Magnetron sputter -

Spectrophotometer

Spectrophotometer- FT-IR, 1200~28000nm

- Spectrophotometer, 185~3300nm -

Cutting Machine

Cutting Machine* Dicing saw

- Liner cutting tolerance ±0.01~0.02mm -

Cutting Machine

Cutting Machine* CNC scriber

- Varied by substrate thickness

- Circular cutting tolerance ±0.1mm

- Linear cutting tolerance ±0.02mm -

Cutting Machine

Cutting Machine* Shape Router

- Cutting precision: tolerance ±0.05mm

- Routing size: up to 305x305mm -

Dimensional and Defect Inspector

Dimensional and Defect Inspector- microscope - 500x

- microscope - 90x(digital), 5x(optical) -

Visual Inspection

Visual Inspection- Reference by MIL-PRF-13830

-

Environmental Chamber

Environmental Chamber- Temp.: -40~150 degree C

- Humidity Range: 20%~98% R.H -

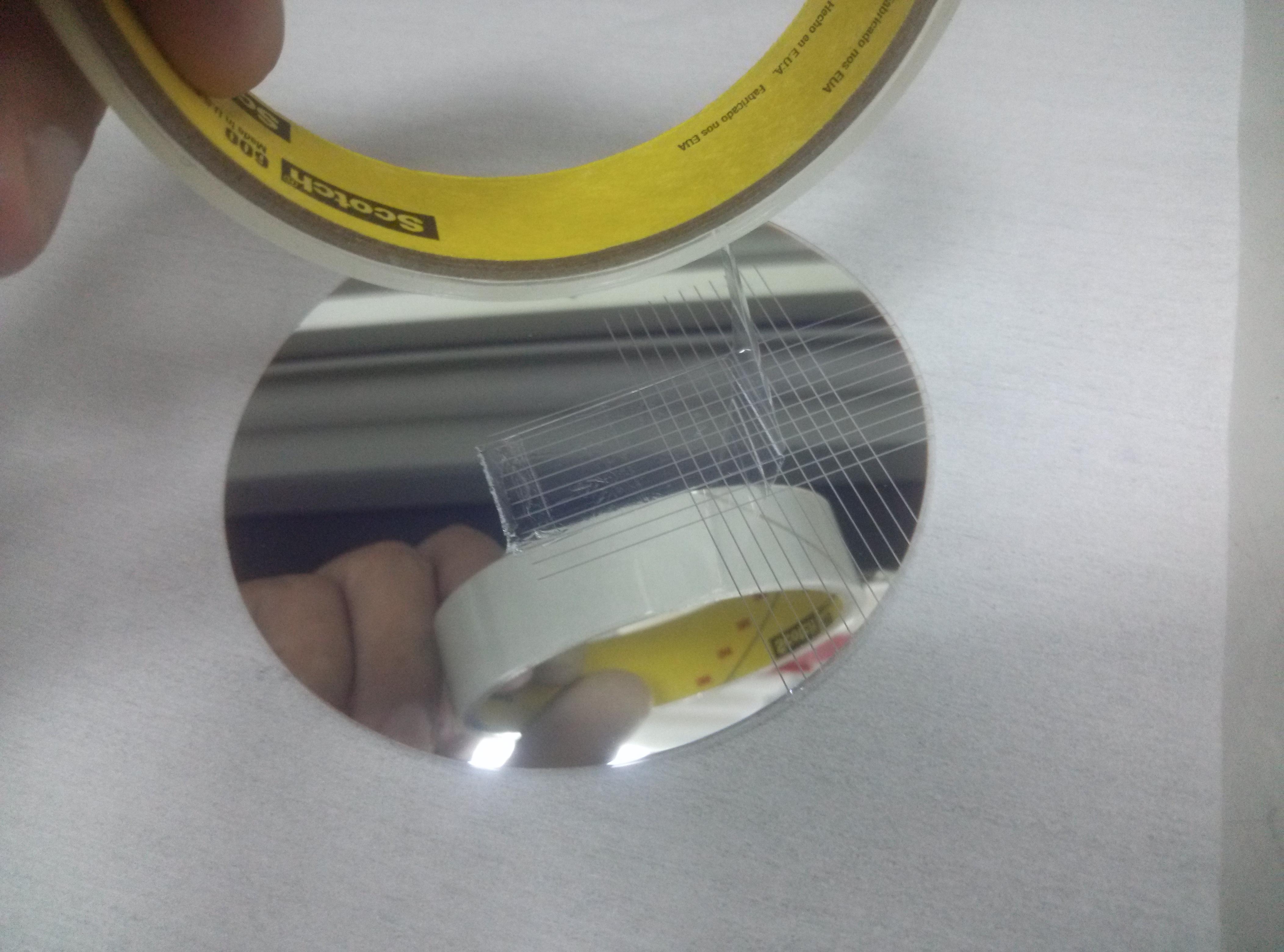

Peeling Test

Peeling Test- Reference by ISO 9211-4-2006

-

Assembly Line

Assembly Line- 100K+/M capacity for DLP projection components